Aluminum sacrificial anode is one of the types of anodes that can be used for cathodic protection of structures in any type of water. The well-known alloy for aluminum anode is AL-Zn-In. Indium is used as an activator to prevent the formation of Al2O3 oxide layer and increase the efficiency of the anode. Aluminum anode has a higher voltage than zinc, so it is used more than zinc. The capacity of aluminum (2,650 Ah / kg) is about 3.5 times higher than that of zinc (780 Ah / kg). Hence, the total weight of the anode required using aluminum is much less than the zinc anode. Therefore, aluminum anodes are generally more efficient and cost-effective than zinc anodes.

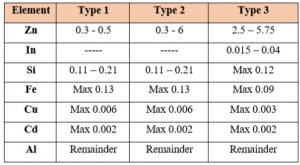

Common standards for aluminum sacrificial anodes include BS 7361, DNV-RP-B401, IPS-M-TP-750, NACE-RP0387, NORSOK M-503 and MIL-DTL-24779B. The insert used in aluminum anodes according to NACE-RP0387 standard must be made of weldable structural steel plates or weldable steel pipe. The chemical composition of the aluminum anode is shown in the table below, which is referred to as Type 3 alloy in DNV-RP-B401.

Ships, boilers, pipelines, tanks, ground and underground, refineries, offshore platforms and marine docks. Aluminum anodes are made in different shapes and dimensions based on the design and request of the customer.

• They are more active than zinc or magnesium anodes.

• Unlike magnesium anodes, they are not dangerous in salt water or salt water.

• Aluminum anodes have a longer life and are the only sacrificial anode that can be used in any type of water (Fresh water or brackish water).

• Protect equipment from corrosion for a long time.

Technical Documents

Datasheet sample of rectangular Aluminum anode with weld connection (Gross Weight= 12.5kg)

Datasheet sample of Platform Aluminum anode (Gross Weight: 13.5 kg)

Datasheet sample of one hole Aluminum anode

Datasheet sample of trapezius zinc anode with weld connection (Gross Weight: 35 kg)

All Rights Reserved for Tavanazob Sana'ati Kavir.