Magnesium anode has a higher voltage than other sacrificial anodes and is most used in cathodic protection of coastal structures (with high electrolytic resistance) in which the use of zinc and aluminum is uneconomical. Magnesium is widely used as a sacrificial anode for cathodic protection of underground and submarine steel structures, ships, submarines, bridges, piers, structures buried in the ground (both packaged and raw) and underground transportation systems.

1) Standard Magnesium Anode (AZ63)

2) High Potential Magnesium Anode (M1C)

Common standards for magnesium anodes include ASTM-B 843, ASTM-G 97, BS 7361, IPS-M-TP-750 and NACE-RP0387. Magnesium anodes are designed and manufactured in different dimensions and shapes depending on the type of application and the request of the client.

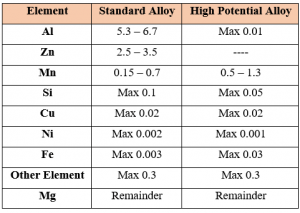

According to ASTM-B 843, the chemical composition of magnesium anode is as follows:

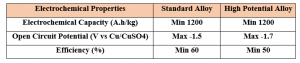

The insert used in magnesium anodes according to NACE-RP0387 standard must be made of galvanized steel. According to BS 7361 standard, the electrochemical properties of magnesium anode are as follows:

The magnesium anode used to protect pipelines, tank floors and other buried installations is usually with a backfill and linen bag. The backfill material, which generally contains gypsum plaster, bentonite and sodium sulfate, rapidly absorbs soil moisture and reduces electrolyte resistance. Therefore, by increasing the anode current, the practical implementation of protection is improved.

Datasheet sample of High Potential Magnesium anode 32Lb

Datasheet sample of one-hole Standard Magnesium anode(AZ63)

Datasheet sample of one-hole High Potential Magnesium anode

Sample report of chemical Analysis of Sacrificial Magnesium Anode

Sample report of Electrochemical Analysis of Sacrificial Magnesium anode

All Rights Reserved for Tavanazob Sana'ati Kavir.